Coal Charcoal Boiler Manual & Automatic

Industrial charcoal fired boiler, burning charcoal to generate heats (hot-water or hot-steam generating).

1) DZL series charcoal boiler, is automatic charcoal feeding chain grate combustion boiler. Fire-tube & water-tubes boiler, has higher thermal efficiency.

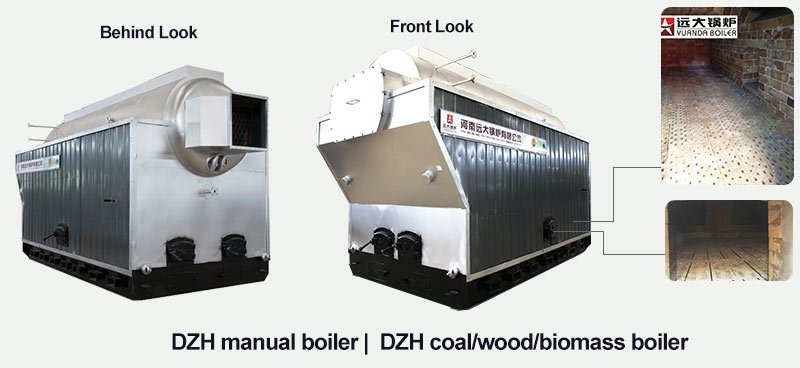

2) DZH series charcoal boiler, need labor working to feed charcoal into combustion device, it has strong fuel adaptability, long life span.

Hot Selling Automatic Charcoal Boiler

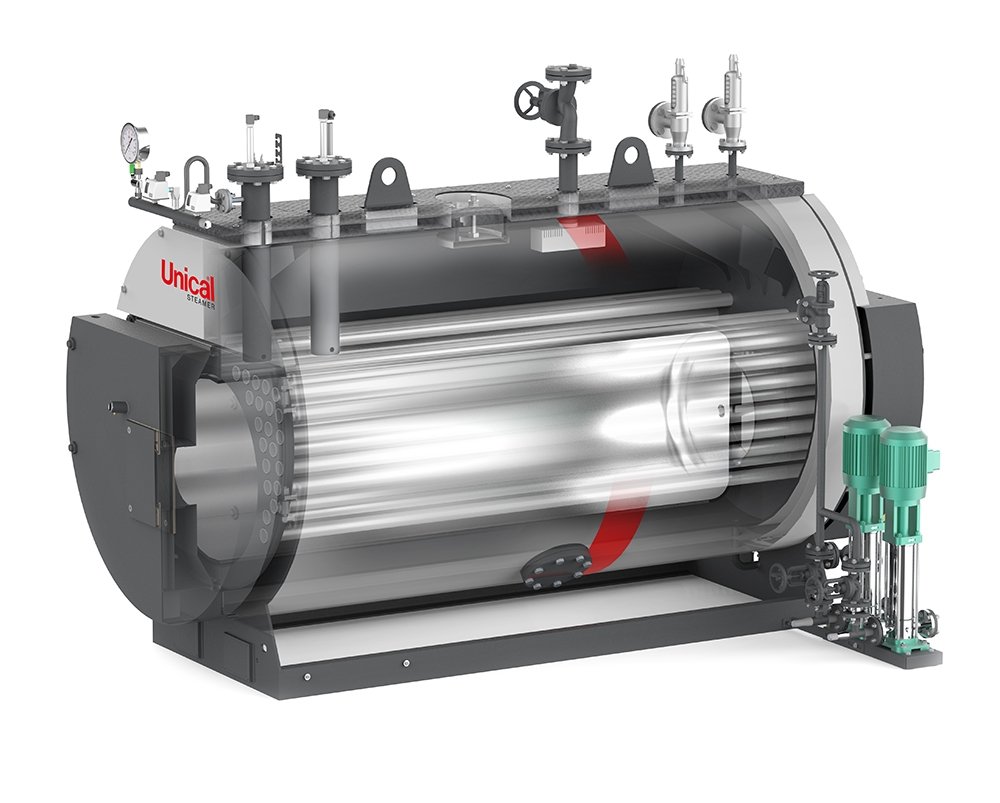

DZL series chain grate coal boiler, it is horizontal three-pass water-tube & fire-tube boiler. DZL use chain grate combustion stoker for coal combustion efficiently, automatically.

1. It could burn coal, charcoal, briquette, biomass, wood, ricehusk, palm shells

2. Water-tube and fire tube use spairally corrugated tubes, enhance heat transferring

3. Furnace arch with upside down “α” flue gas flow, make coal/biomass burning sufficiently

4. Set steam-water separaing equipment, has high-quality & sufficient steam output

Advantages DZL Charcoal Boiler

1. Easy Installation: Fast-assembly leave from factory, easy to transport and install at site.

2. Full Combustion: Reasonable design of furnace structure with best suitable grate device, fuel fired fully.

3. High Efficiency Grate: Chain grate, easy operation, have lots of advantages compared to traditional grate.

4. High Security: Equip with water lack protection and over pressure protection devices, security and reliable.

5. Long Life and Durable: Advanced production processes, strict quality inspection, boiler life span above 20 years.

6. Environmental Protection and Low Noise: Low noise fans, dust remove device, meet local emission requirements.

Features Design Advantages

1. Smoke and dust separator chamber

Separate smoke and dust according to inertia,reduce the original effluent concentration of soot.

2. Optimized design CAD

Choose the best furnace from dozens of options,improve economical efficiency.

3. Convex tube plate

1) Improve tube plate flexibility, so as to reduce the heating stress of welded sew at the pipe end.

2) Prevent tube plate cracking, cancel bracing,simplify the structure.

4. Large size of simple circulation loop drop pipe and lower set box

Increase the flow rate of water on water cooling wall in order to prevent subcooled boiling. To prevent pipe explosion,Increase the reliability of water cycle

5. New pattern of furnace arch

Strengthen the combustion, could burn kinds of fuel: wood, coal and biomass, improve combustion efficiency.

Other option DZH Manual charcoal boiler

Manual feeding charcoal fired boiler, need labor work to feed coal.

DZ Series Charcoal Boiler Technical Parameter

| Model | Rated Capacity (t/h) | Rated Pressure (Mpa) | Rated Steam Temperature (℃) | Feed Temperature (℃) | Thermal Efficiency (%) | Boiler Water Volume (m³) | Exhaust Temperature (℃) | Fuel Consumption (Kg/h) | Max Transportation Weight (t) |

|---|---|---|---|---|---|---|---|---|---|

| DZH1 | 1 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 3.15 | 127.25 | 192.32 | 9 |

| DZL1 | 1 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 3.15 | 113.34 | 190.42 | 13.5 |

| DZH2 | 2 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 4.75 | 126.41 | 386.47 | 15 |

| DZL2 | 2 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 4.77 | 106.34 | 393.77 | 22 |

| DZH4 | 4 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 7.7 | 137.25 | 782.29 | 18.5 |

| DZL4 | 4 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 8.2 | 124.49 | 756.89 | 27.6 |

| DZH6 | 6 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 7.4 | 146.83 | 1169.57 | 25 |

| DZL6 | 6 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 8.1 | 137.29 | 1148.68 | 35 |

| DZL8 | 8 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 9.6 | 141.06 | 1602.44 | 38 |

Note: Parameters are for reference only. Any changes should follow the factory technical data.

Discover our range: Steam Boilers, Steam Generators, Hot Water Boilers, Thermal Oil Boilers, Thermic Fluid Heaters, Hot Air Furnaces. Capacities from 100kg to 20000kg, and 100kw to 14000kw. Fuel options: Charcoal, Briquette, Coal, Biomass, Wood, Solid Waste.

Contact us to get more details!

Call: +8801614636264